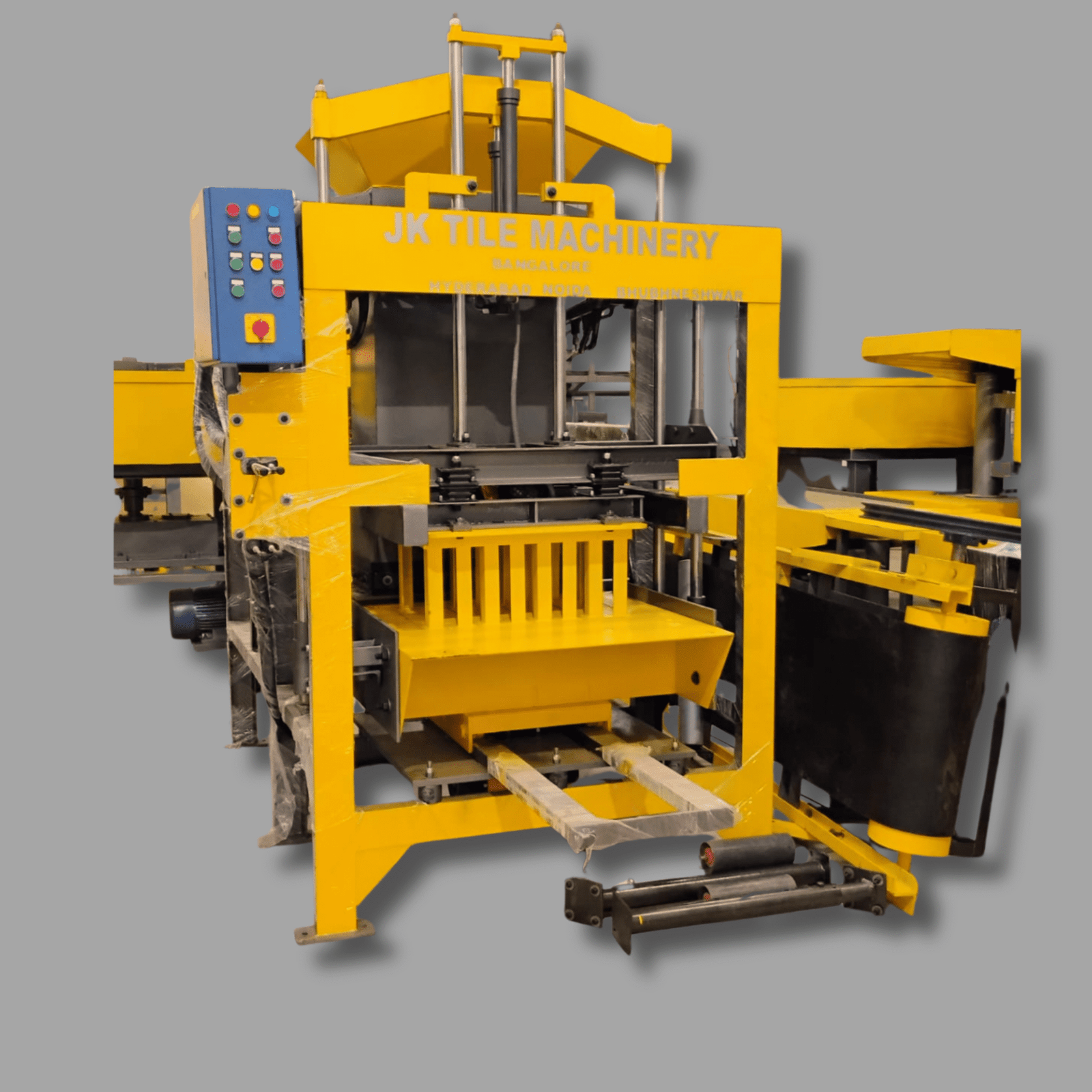

HIGHLY EFFICIENT

HOLLOW BLOCK MAKING MACHINE

Block Making Machine

JKTM PSAT TR1650 Block Master single Stroke semi -Automatic egg laying platform type hollow and solid block making machine with Hydro- Vibro Tech

Major Components of Block Making Machine

Pan Mixer

SPECIFICATION

Dimension : 1524mm X 450mm

motor: 7.5 HP Crompton® Greaves

Gear Box: 22 liters

Blade System: Roller / Blade

Capacity: 450 Kgs

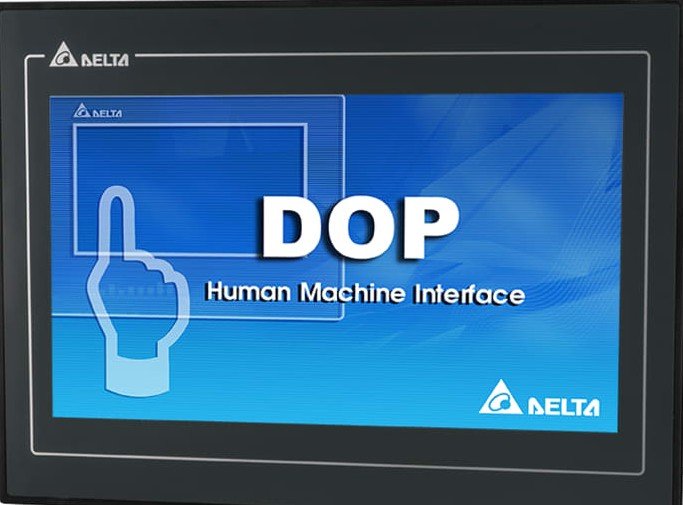

PLC Computerized Panel

SPECIFICATION

- Hydraulic: 35 LPM Oyler/Yuken Vane pump and assembly(HSCS) Hydraulic

Speed Control System. - Electronic Parts: All heavy Load contractors, MCCBs, Delay timers, switch

circuits, start/stop buttons, complete wiring and other electronic or electrical

components are supremely branded. - Panel Body: Dust & vermin proof Panel suitable for bottom cable entry.

- Vibration Auto: Auto-timer vibration facility with limit switch safety feature.

Main Hydraulic Punch

SPECIFICATION

- 4/6/9/12 etc. Cavity Punch

- 31 grade iron.

- High Density Tempered

- 3 HP Vibration motor.

- vibrator type – double/ Triple (Optional in JKTM-SAT-1550 Model)

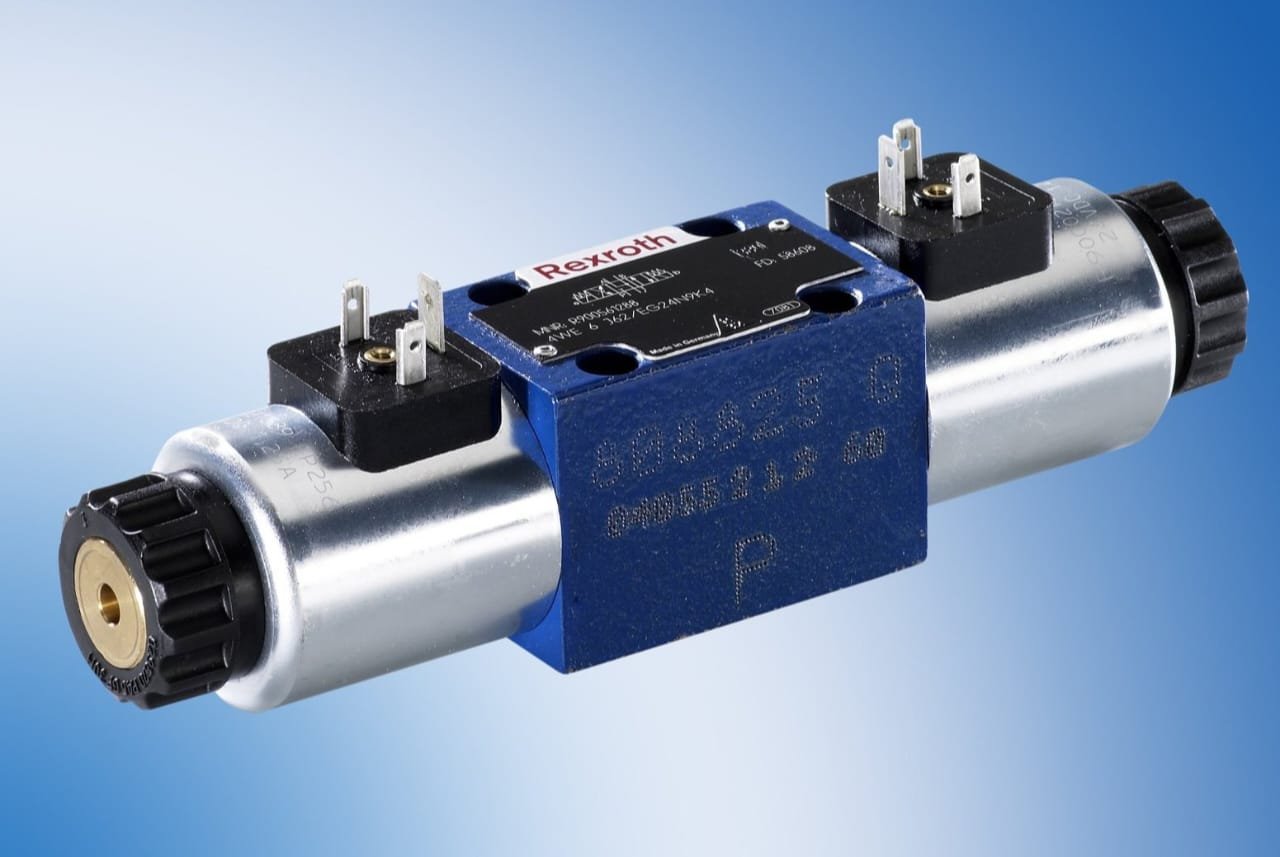

Hydraulic pressure Control mobile Lever valve block set

SPECIFICATION

- Streamline your concrete production with our advanced main feeder system. The integrated hopper ensures precise and consistent material flow, guaranteeing accurate batching and superior quality concrete every time. Its compact design and efficient operation minimize waste and maximize productivity for optimal project delivery. MS Angles And Channels from VIZAG & SAIL LTD.

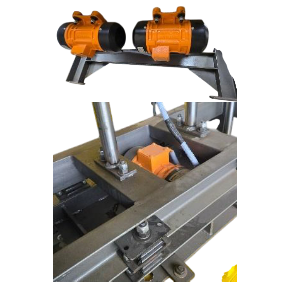

Triple Vibration Technology (TRI-3 drive vibro tech)

SPECIFICATION

- Triple Vibration TRI-3 drive technology for

- Heavy duty three mechanical Mega Vibrators

- High Density EPDM Tempered iron Fittings for Anti-shock and absorption

- 2.5 HP(1 HP + 1 HP + 0.5 HP) Vibration motor connected with two mechanical vibrators

- Vibrator type – triple vibration

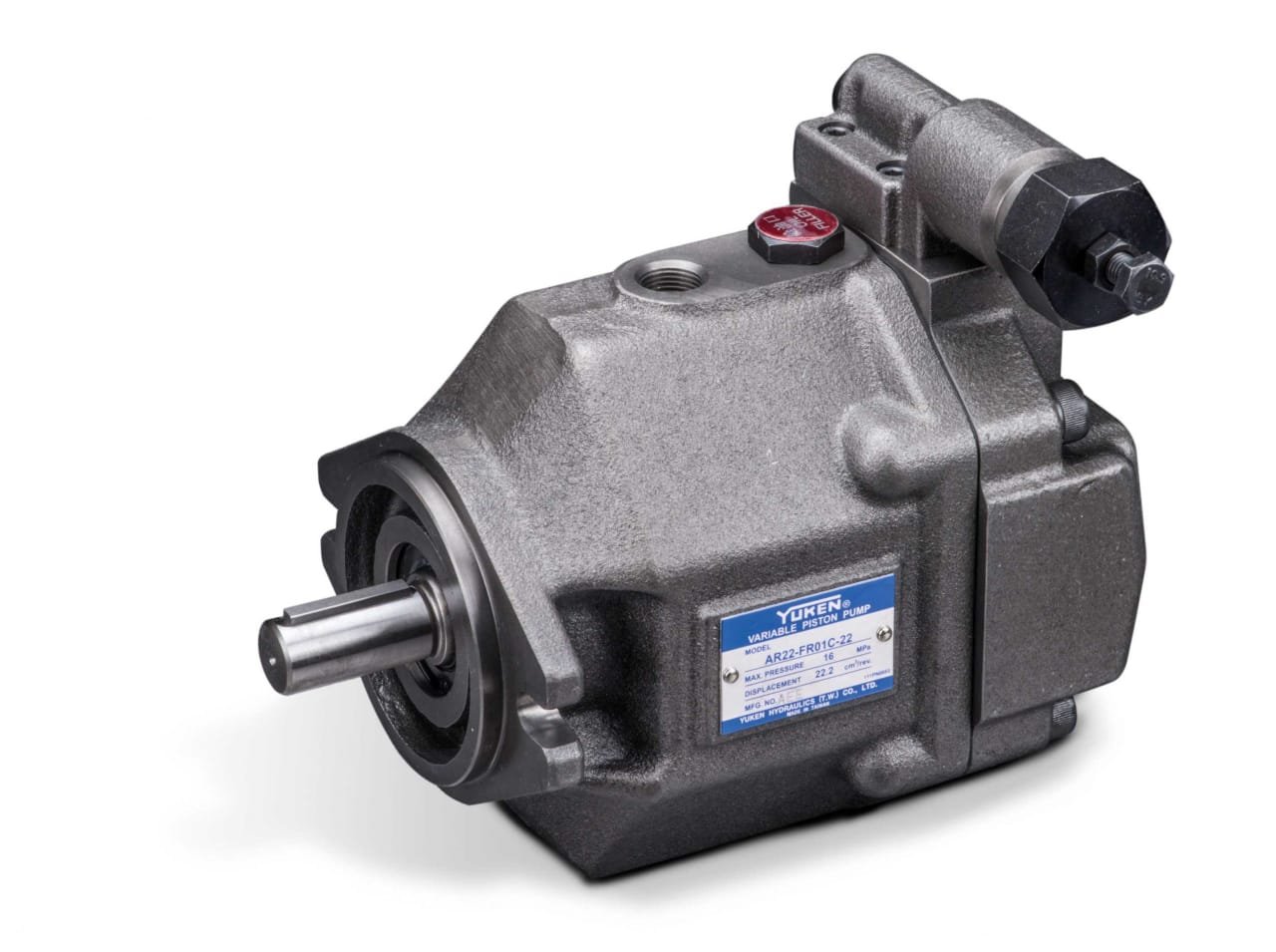

Pressure Power Pack Assembly

SPECIFICATION

- 5 Hp Pressure induction motor

- 15 liters oil tank capacity

- 45 LPM Oyler/Yuken VANE pump

- Heavy Duty Anti-heat hose pipe and fitting

- Heavy Duty rajhans/techno land oil seal.

- Hydraulic: 35 LPM Oyler/Yuken Vane pump and assembly(HSCS) Hydraulic Speed Control System.

Concrete Feeder + hopper System

SPECIFICATION

- Streamline your concrete production with our advanced main feeder system. The integrated hopper ensures precise and consistent material flow, guaranteeing accurate batching and superior quality concrete every time. Its compact design and efficient operation minimize waste and maximize productivity for optimal project delivery. MS Angles And Channels from VIZAG & SAIL LTD.

Finished Product Ejector System

SPECIFICATION

- Maximize efficiency with our automated ejector system. It rapidly and precisely discharges finished concrete products from molds, eliminating manual labor and accelerating your production cycle. Minimize product damage, increase throughput, and ensure consistent quality with this essential automation solution.

Conveyor Belt System

SPECIFICATION

- Motor : 2 Hp

- Gear Box : 3 liters

- To feed the mix from the pan mix to the concrete hopper storage system, Maximize efficiency with our automated conveyor system. It rapidly and precisely discharges finished concrete mortar into the hopper storage system, operated automatically by PLC panel Unit.

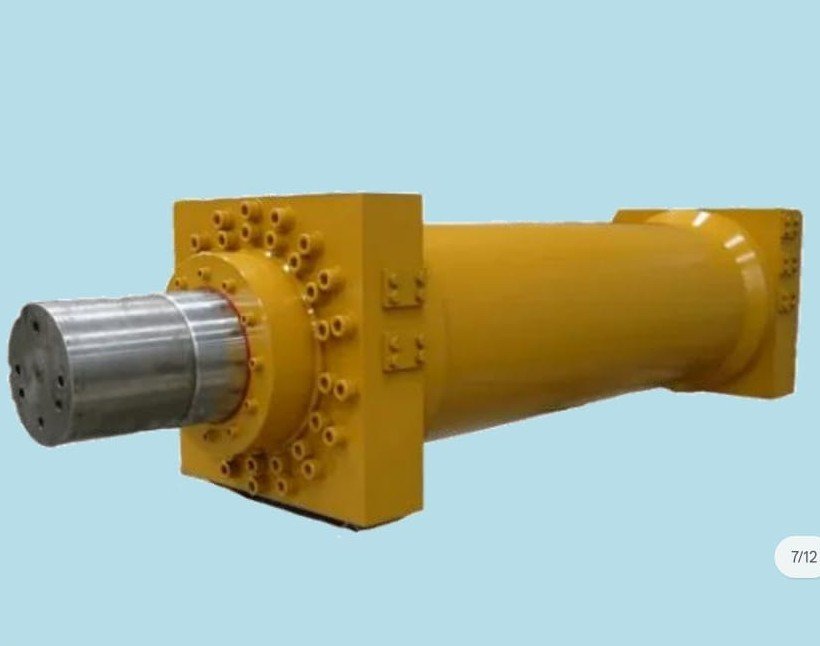

Hydraulic cylinders punch and Cavity System

SPECIFICATION

- Introducing first EN 8 Anti Heat/bend Hydraulic technology to achieve

- Best Strength and Designed Impression on Each piece.

- Precised Dimensional Accuracy.

- Uniform Size with Controlled Height.

- Maximize efficiency with our semi automated Hydraulic cylinders punch and Cavity System. Guided rods with en8 grade rods and bushes for extreme durability.

Major Parts of Block Making Machine

PRODUCT SPECIFICATION

| No | JKSAT-BlockMaster 1150 Single Stroke | Production Type |

|---|---|---|

| 1 | Overall Dimension | 50Lx60Bx4H |

| 2 | Total Power | 14HP/10.5kw |

| 3 | Vibration Suspension Ty | Anti Vibration JK Rubber Paded U Mounting Brackets |

| 4 | Vibration Frequency | 70-80 Heartz (Hz) |

| 5 | Cycle Time per minute | 40 to 45 secs per mould |

| 6 | Sheet Thickness | 8 MM Top Sheet Thickness/ Bottom Plate 12 MM/side Plate 8 MM |

| 7 | Power Supply | 3 Phase Commercial Connection. |

| 8 | Maximum Block Height | Variable Depends On Product |

| 9 | Automation Grade | Semi Automatic+manual |

| 10 | End Production Type | Paver Block, Cement Tiles, Concrete Block, Parking Tiles, Interlocking Tiles Etc. |

Final Products

Concrete Blocks

Hollow Blocks

Cement Bricks