HIGHLY EFFICIENT

Fully automatic Multi purpose concrete Bricks and blocks making machine

JK-FAT-EV 2200 EVEREST

Block Making Machine

Fully automatic Multi purpose concrete Bricks and blocks making machine

Major Components of Block Making Machine

Main Machine & Technology

SPECIFICATION

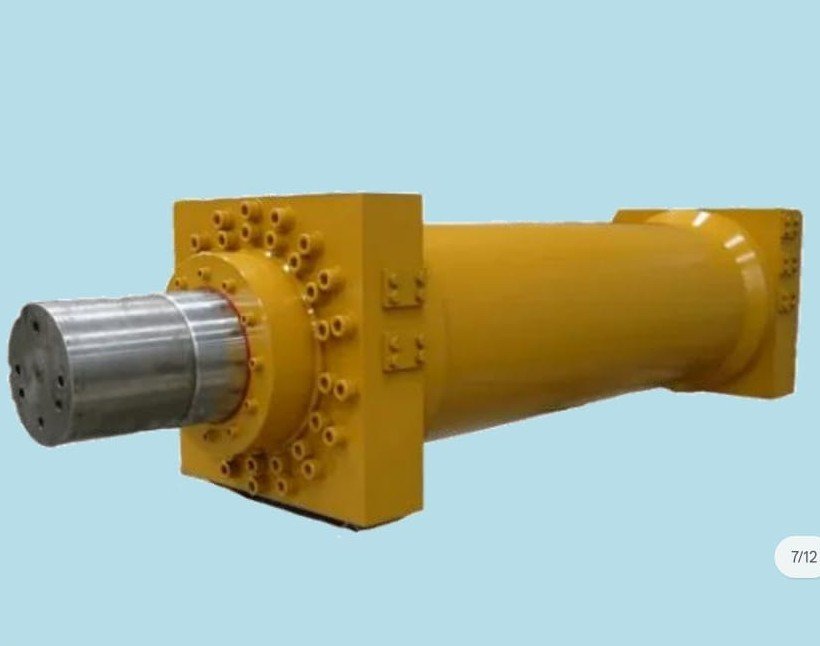

- Heavy MS steel plate Body 22 to 25mm thickness, Hydraulic Main jack & Two Side cylinder with Hydraulic oil seal Technoland / Rajhans.

- 50 to 60 Tones Pressure with Vertical Vibration, Automatic Double Feeder facility, Sensor System Machine, Auto. Stacking system & Auto. PLC based Comp. Panel board system.

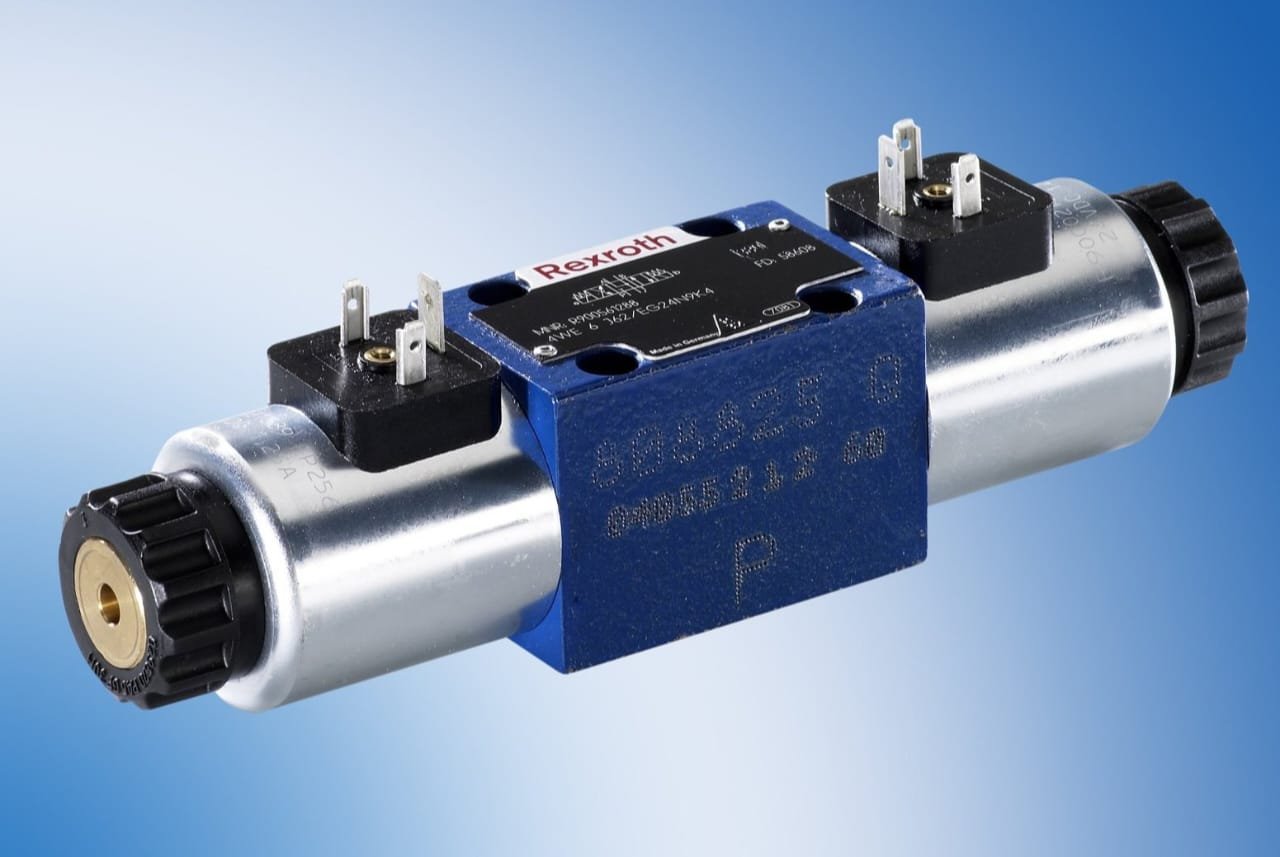

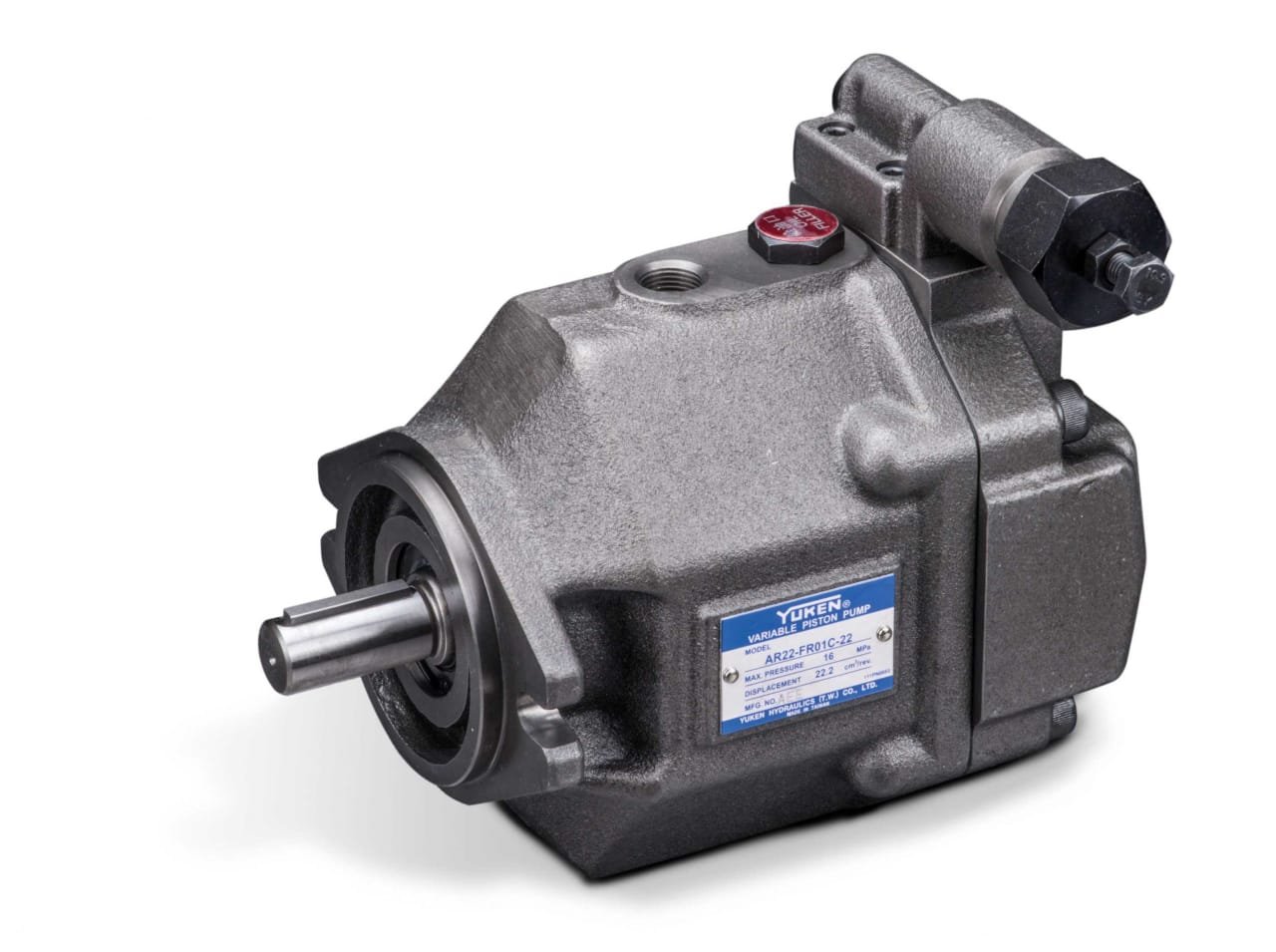

Power pack

SPECIFICATION

- Hydraulic Pressure 80-90 Tonnage.

- 10 HP JKTM Motor (Crompton, havelles ) For Main power pack with copper winding.

- 480 Liters Oil Tank with Oil Cooling System.

- Yuken® Plunger Pump.

- Pressure Meter Scientific/Micro.

- Sonoligh Control Valve Rexroth®

- Bosch Speed Gear Pump.

- Hydraulic Jack Oil Seal Technoland/ Ranjhans.

Automation Wi fi PLC Panel Computerized Unit

SPECIFICATION

- (EPCS)Electronic Pressure Control System.

- MS Steel Sensor System With Auto Stop Facility.

- (HSCS) Hydraulic Speed Control System.

- Electronics Parts By Siemens® & Delta.

- Dust & vermin proof Panel suitable for bottom cable entry.

Conveyer belt System

SPECIFICATION

- Dimension(Belt) : 6850mm(23feet) X 500mm X 10mm

- motor : 2 HP

- Gear Box : 3 liters

- To feed the mix from the pan mix to the Brick, Press: Capacity

2 Tons / hour Power (Motor) Bottom End 2 hp. 1440 RPM Crompton motor Storage intermittent Bin flow Regulation By heavy rollers Gear Box 300 - 30 *1 RPM

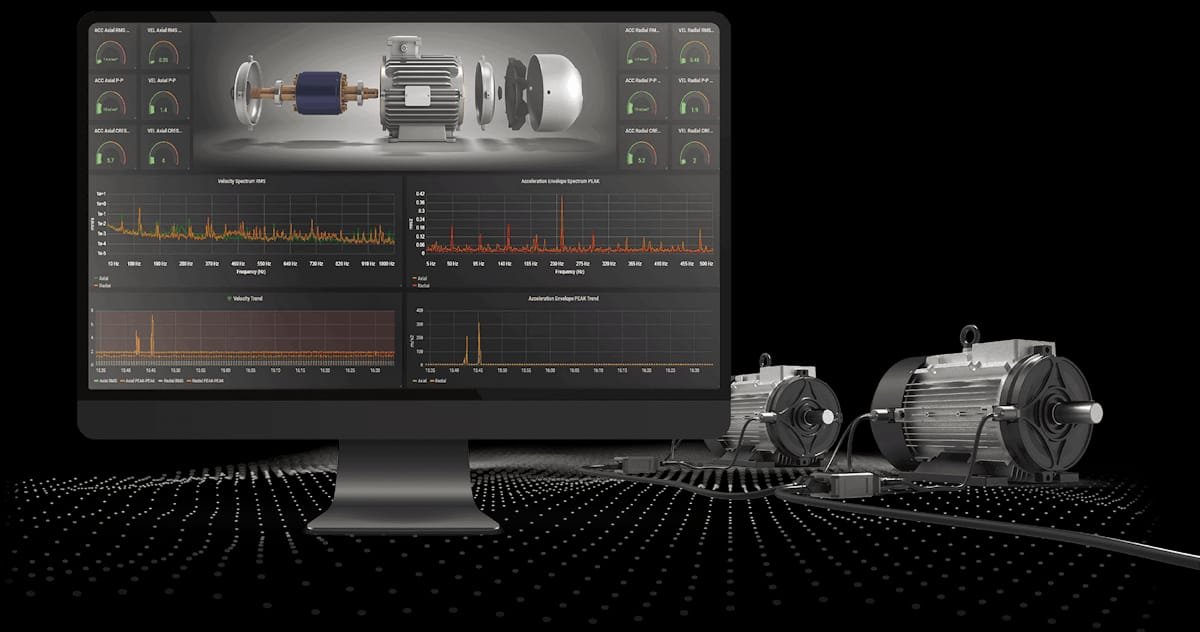

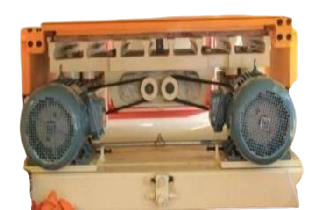

Verticle Vibration system Twin drive

SPECIFICATION

- Best Strength and Designed Impression on Each piece.

- Precised Dimensional Accuracy.

- Uniform Size with Controlled Height.

- 7.5Hp + 7.5 Hp Crompton/Havells motor for generate the Vibration in mould for quality purpose which is remove air bubbles in bricks & increase the strength of bricks & block with combine Technology.

- Bottom Two 5.25 kW Vibration Motors offer Strong Vibration force, Largely improve density of the blocks Gives accurate height to each block and précised

dimensions

Auto Stacker System

SPECIFICATION

- Automatic pallets stacking system for smooth & speedy operation.

- Power require 3 HP (1 Hp + 1 Hp + 1 Hp).

- Hydraulic Lifting system for running the stacker.

- Controlled by variable frequency drive

Color mixer Machine

SPECIFICATION

- Capacity : 100 kgs to 125 kgs / Per Batch Power (Motor): 2 Hp. – 1440 rpm Crompton/Havells Motor Manufacturing: Mixing of raw Materials of Top Layer Rubber Mould, Paver Block.

Hydraulic Trolley

SPECIFICATION

- Hydraulic Trolley Manufactured using high-grade raw material, These Trucks are known for their high performance, Durability, strong construction and low maintenance. - Hand operated Hydraulic system.

Color Feeder System

SPECIFICATION

- fully automatic color secondary feeder system Attached with computerized plc panel to give efficient and

proper color input feeding.

Concrete Main Feeder System

SPECIFICATION

- fully automatic concrete main feeder system

driven by twin directional motorized system

Attached with computersied plc panel to give efficient and proper concrete inpur feeding.

Roller/Blade Pan mixer

SPECIFICATION

- 1800 mm diameter.

- -10 to 12mm MS steel plate Circle & Side wall 4 + 4mm.

- 500 to 650 kg. Raw materials mixing capacity.

- Mixing by Rollers and Hand faced scrapers.

- 7.5 HP + 7.5 Hp Crompton / Siemens / ABB / Havells motor.

- Heavy body Gearbox, SKF(ISI)/NBC Bearing,

- Discharge (Manual): Bottom door opening.

- Material charge: Manual of conveyor

Major Parts of Block Making Machine

PRODUCT SPECIFICATION

| No | JKSAT-BlockMaster 1150 Single Stroke | Production Type |

|---|---|---|

| 1 | Overall Dimension | 50Lx60Bx4H |

| 2 | Total Power | 14HP/10.5kw |

| 3 | Vibration Suspension Ty | Anti Vibration JK Rubber Paded U Mounting Brackets |

| 4 | Vibration Frequency | 70-80 Heartz (Hz) |

| 5 | Cycle Time per minute | 40 to 45 secs per mould |

| 6 | Pallet Size | 28" inch x 24" inch (25mm) Iron Method Wooden Pallet |

| 7 | Sheet Thickness | 8 MM Top Sheet Thickness/ Bottom Plate 12 MM/side Plate 8 MM |

| 8 | Power Supply | 3 Phase Commercial Connection. |

| 9 | Maximum Block Height | Variable Depends On Product |

| 10 | Automation Grade | Semi Automatic+manual |

| 11 | End Production Type | Paver Block, Cement Tiles, Concrete Block, Parking Tiles, Interlocking Tiles Etc. |

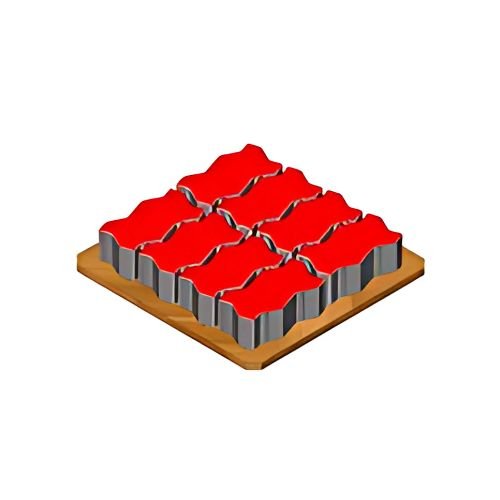

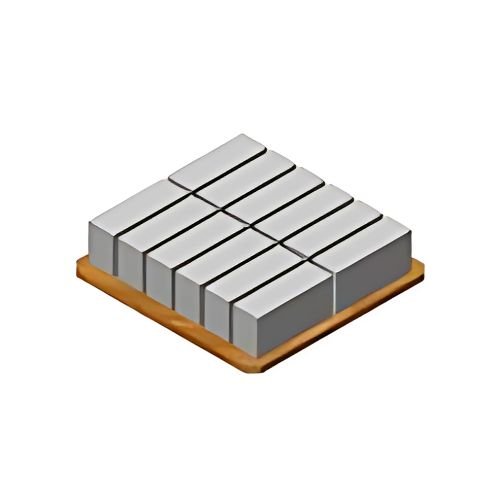

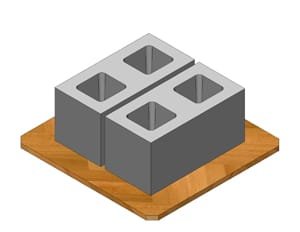

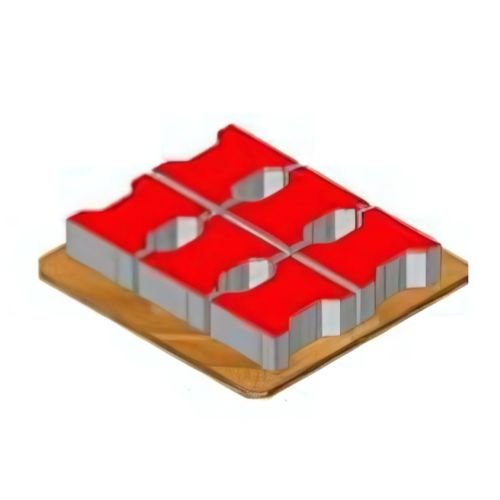

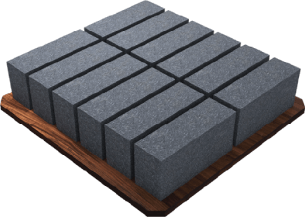

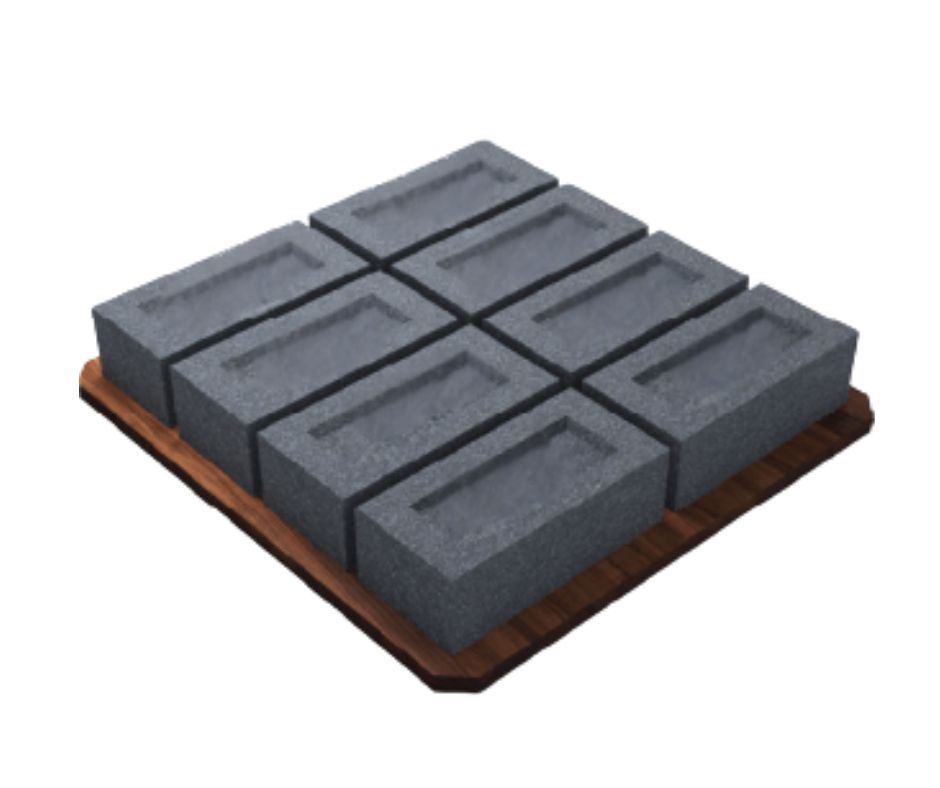

Final Products